Temperature transmitters

Here are the available transmitters:

- Fieldbus

- Profibus

- Smart Hart

- 4÷20mA

Also available in the Ex ia-b configuration.

Compensated connectors

There is a wide range of compensated and not compensated connectors, in accordance with international standards for thermocouples and resistance thermometers.

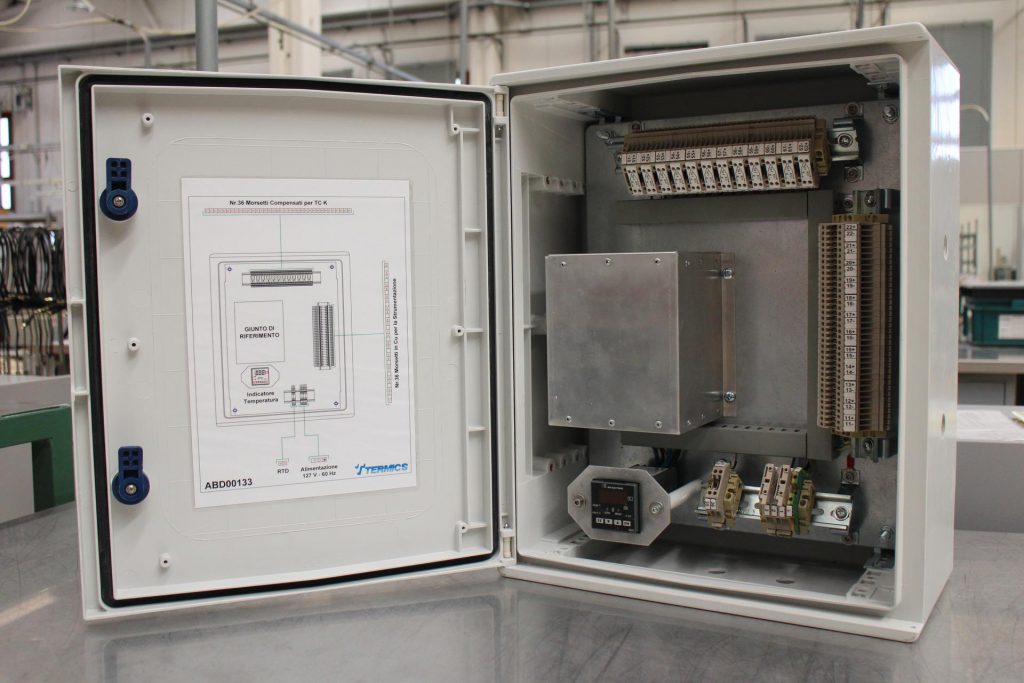

Reference joint / smart box

Production of reference joints, also called compensating or cold joints (Exe – ExnA certified or standard ones) for any kind of thermocouple. This type of cold junction is used as a reference point for measuring the temperature.

Thermowells

Thermowells are designed to protect probes against adverse operating conditions such as corrosive agents, collisions and high pressure. Moreover, their use allows for quick and easy interchangeability of the probe without the need to “open” the process. The wells are manufactured according to national / international standards (ENI – NUOVO PIGNONE – SHELL – SAUDI ARAMCO, etc.) and the materials (AISI 304 – 310 – 316 – 321 – 347 – INCONEL – HASTELLOY – MONEL – DUPLEX – SUPERDUPLEX – HAYNES – TITANIUM – TANTALUM). For heavy-duty applications (steam), Termics provides verification in accordance with ASMEPTC 19.3.

Compensated cables

Compensated and extension cables (thermocouples) and extension cords (resistance thermometers) are very important in the field of thermo-elements. The cables are chosen for the execution of the probes according to the application field.

| Sheath Material | Temperature field | General properties |

| TEFLON | -200 ÷ +260°C | Excellent properties such as resistance to chemical agents, dielectric and mechanical characteristics. |

| KAPTON | -260 ÷ +400°C | Excellent properties such as resistance to chemical agents, dielectric and mechanical characteristics. |

| ELECTRIC GLASS | Fino a +500°C | Good resistance to high temperatures. Small overall dimensions, but poor resistance to abrasion and hydrocarbons. |

| SILICON RUBBER | -60 ÷ +250°C | Good resistance and high flexibility at low temperatures. |

| PVC | -55 ÷ +100°C | The use of special additives can improve the chemical resistance and the resistance to heat, cold, etc. |

| CERAMIC FIBRE | 0-900°C | Excellent resistance to high temperatures, but poor resistance to humidity |

Ceramic sheaths

The insulators and ceramic sheaths are generally used for probes suitable to withstand high temperatures.

| Sheath Material | Temperature field | General properties |

| ALSINT 710 | Fino a +1900°C | Waterproof ceramic sheath resistant to thermal and mechanical shocks. Used in ceramic industries, high-temperature furnaces and glassworks. Impermeable to gases at high temperatures. |

| PYTAGORAS 610 | Fino a +1600°C | Waterproof ceramic sheath resistant to thermal shocks. Used in ceramic industries, high-temperature furnaces and glassworks. |

| SILLIMANTIN 530 | Fino a +1650°C | Non-waterproof ceramic sheath. |

Request information